{{ pageName }}

-

Nonwoven Fabric

-

Nanocellulose

Nonwoven Fabric

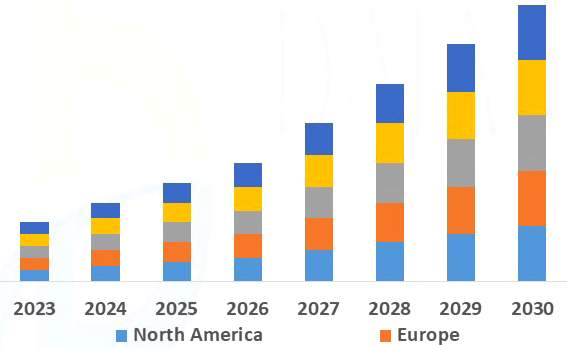

The global non-woven fabric market is projected to grow from USD 46.74 million in 2022 to USD 82.93 million by 2030.

It is anticipated to expand at a Compound Annual Growth Rate (CAGR) of 7.43% during the period from 2023 to 2030.

Industrial Trends and Forecast for 2030

Source : Data Bridge, global non-woven fabric market (2023)

Scope and Segmentation of the Nonwoven Fabric Market

(Units: $1 million, %)

| REPORT METRIC | DETAILS |

|---|---|

| Forecast Period | 2023 to 2030 |

| Base Year | 2022 |

| Historic Years | 2021 (Customizable to 2015-2020) |

| Quantitative Units | Revenue in USD Million, Pricing in USD |

| Segments Covered | Technology (Spunlaid, Drylaid, Wetlaid, Others), Material (Polypropylene (PP), Polyethylene Terephthalate (PET), Polyethylene (PE), Rayon, Wood Pulp, Bi-Component (BICO), Others), Layer (Single-layer, Multilayer), Function (Disposable, Non-Disposable), Application (Construction, Textile, Personal Care, Filtration, Others) |

| Countries Covered | U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific , Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa, Brazil, Argentina and Rest of South America. |

| Market Players Covered | Kimberly-Clark Corporation (U.S.) DuPont de Nemours, Inc. (U.S.), Berry Global Group, Inc. (U.S.), Ahlstrom-Munksjö (Finland), Fitesa (Brazil), Freudenberg Group (Germany), Suominen Corporation (Finland), Avgol Nonwovens (Israel), Toray Industries, Inc. (Japan), Fibertex Nonwovens A/S (Denmark), Mitsui Chemicals, Inc. (Japan), Asahi Kasei Corporation (Japan), Sandler AG (Germany) |

| Market Opportunities | Innovative product development Expanding geographical reach |

Source : Data Bridge, global non-woven fabric market (2023)

Nanocellulose

The global nanocellulose market surpassed $398.4 million in 2022, with an estimated compound annual growth rate (CAGR) of 19.1% from 2023 to 2033.

Objectives and Significance of Nanocellulose Research

As the highest-tier plan for national science and technology development, the Basic Plan for Science and Technology identifies 12 major national strategic technologies to be intensively fostered over a five-year period, three of which pertain to energy-related technologies. The situation is fraught with national challenges such as the repercussions of Japanese export restrictions, the US-China trade dispute inciting a competition for technological supremacy, supply chain crises, and climate change. Major countries are articulating their science and technology strategies to maintain and secure technological leadership and address national issues. Similarly, there is a growing recognition domestically of the need to indigenize and become self-reliant in securing carbon-neutral and eco-friendly technologies.

SNE Research, a market research firm specializing in lithium-ion batteries, reported that the market for the four key materials of lithium-ion batteries (cathode, anode, electrolyte, and separator) was valued at USD 54.9 billion (approximately KRW 70 trillion) in 2022. With the expansion of the electric vehicle battery market moving beyond China into the US and European markets, the demand for these materials is expected to drive the market size to USD 147.6 billion (approximately KRW 192 trillion) in 2023. There's a consensus that lithium-ion batteries are the best-performing among existing secondary batteries. They are currently the focal point of the ubiquitous era as a primary source of mobile energy and are rapidly expanding into applications such as PHEVs (plug-in hybrid electric vehicles) and energy storage systems (ESS). Amidst this surging demand and interest, there's also a growing consumer expectation for high-capacity and high-output performance of lithium-ion batteries, as well as concerns regarding safety against explosions and the stability of raw material supply. In response, the National Institute of Forest Science, through collaboration, has continuously developed technologies using nanocellulose, a wood-based cellulose nanomaterial, to overcome the limitations of current secondary batteries. This effort has significantly unlocked positive potentials in lithium-ion batteries in terms of high energy density, safety against explosions, and sustainable raw material supply.

Nanocellulose can be easily manufactured by grinding cellulose extracted from wood, which is readily available on Earth. Cellulose is produced at a rate of about 10g per day from a single tree (with an annual global production predicted to exceed 1 trillion tons). For these reasons, nanocellulose is both a renewable and environmentally friendly material. Furthermore, its versatility in various advanced material applications has been proven through numerous studies, making nanocellulose a promising raw material to address worsening environmental issues and a revolutionary material that can strengthen national technological capabilities in sustainable and eco-friendly advanced materials.

The development of petrochemical-based materials is anticipated to encounter limitations due to carbon-neutral and eco-friendly policies. Rechargeable energy storage systems are moving towards achieving high energy/power density, long charge/discharge cycle life, high operating voltage, safety robustness, and cost competitiveness, along with flexibility, miniaturization, and form factor. Conventional energy storage systems typically comprise anodes, cathodes, electrolytes, and separators based on inorganic/metal compounds, carbonaceous materials, and hydrocarbons derived from petroleum. However, these traditional materials may struggle to meet the escalating requirements of energy storage systems, necessitating the exploration of new chemical substances beyond conventional methods.

Among the numerous candidate materials explored to date, nanocellulose has garnered significant attention as an exceptional 1D element for energy storage systems due to its unique structural characteristics, superior properties, natural abundance, and environmental friendliness. The growing interest in nanocellulose for the rapidly expanding energy storage systems can also be observed in the increasing number of research publications in this field annually. Nanocellulose can be used as a key element in electrodes, electrolytes, and separators. The integration of nanocellulose, an eco-friendly new material produced by applying nanotechnology to wood, with lithium-ion batteries capable of generating eco-friendly energy, appears to be a next-generation convergence technology that can transcend the current state of lithium-ion batteries. This underscores the need for proactive acquisition and domestication of related technologies.

In this context, this research material aims to provide information on the application technology of nanocellulose, developed in collaboration with the National Institute of Forest Science, for lithium-ion batteries, highlighting the importance of advancing and nationalizing the associated technologies.

Source : Forestry Science Institute

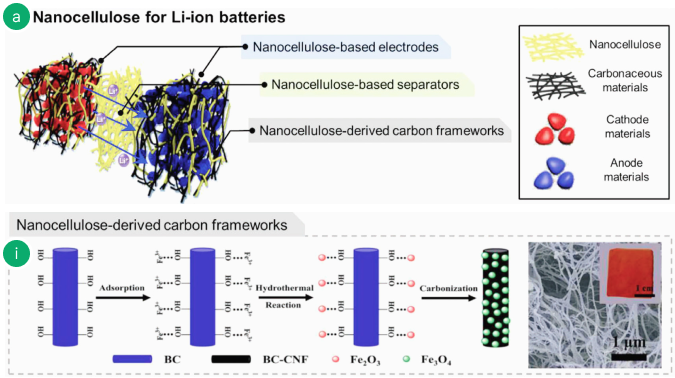

NanoCellulose-Based Electrodes, Batteries, and Carbon Materials for Lithium-Ion Batteries

a) Conceptual diagram depicting the application of nanocellulose in lithium-ion batteries

b) Electronic conductivity of MFC-graphite cathodes as a function of bending radius

c) Photograph and SEM image of CNF/LiFePO4 paper electrode

d) Cycling performance of paper battery (illustrating components before and after folding)

e) SEM image of paper battery cross-section (showing mechanical flexibility)

f) Overview, photographs, and cross-section SEM image of flexible LiFePO4 (cathode) and Li4Ti5O12 (anode) SEA

g) Photograph of high-density (thickness: approximately 1400 µm) CM cathode with dimensional tolerance (illustrating improved structural stability compared to conventional cathode with thickness: approximately 500 µm)

h) Folding process for creating paper cell and electrochemical activity photograph of the resulting cell

i) Synthesis process and schematic SEM image of Fe3O4-carbon nanofiber aerogel derived from BC

Source : Forestry Science Institute

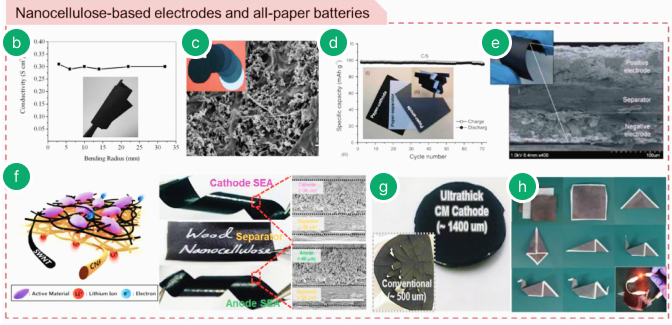

NanoCellulose-Based Solid Composite Electrolyte and Separator for Lithium Secondary Batteries

a) Photograph of GPE membrane composed of CNF and methacrylic polymer matrix (illustrating absorption of liquid electrolyte after 2 hours).

b) SEM image of CNF separator [IPA/water = 95/5 (v/v)].

c) SEM image of S-CNF separator (SiO2 content = 5%).

d) Comparison of wettability of PP/PE/PP separator and CNF separator with liquid electrolyte

e) Dimensional changes (area-based) of PP/PE/PP separator and CNF separator after exposure to 150°C for 0.5 hours

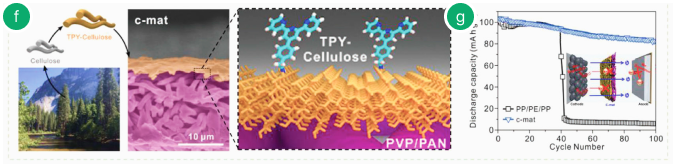

f) Schematic representation of functionalized CNF integrated nanomatte separator (c-mat) composed of TPY-CNF layers and electrospun PVP/PAN support layer

g) High-temperature (60°C) cycling performance of a battery assembled with c-mat separator and LiMnO2 cathode

Source : Forestry Science Institute