{{ pageName }}

-

Eco-Friendly Biodegradable 100% PLA Nonwoven Fabric

-

GRS Flame Retardant Nonwoven Fabric

-

Sustained Leadership Functionality PP SB Nonwoven Fabric

Eco-Friendly Biodegradable 100% PLA Nonwoven Fabric

The material boasts superior processability and mechanical strength, achieved through the modification of conventional PLA materials, enabling low-temperature extrusion with enhanced melt flow properties (at a benchmark of 230°C, ranging from 450 to 5,000g/10 min grade).

-

Product Name

PLA MB Nonwoven Fabric

-

Category / Type

Industrial Material / Nonwoven Fabric

-

Composition

100% PLA

-

Finish / Weight(g/sqm)

Unprocessed / 20~100

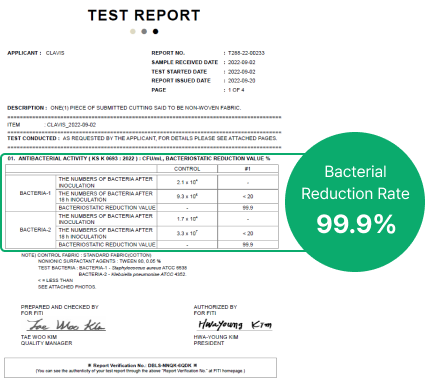

PLA Melt-bloom Nonwoven Antimicrobial Analysis Results

-

*Antimicrobial properties (KS K 0693)

-

Table for results of PLA Melt-bloom Nonwoven antimicrobial analysis Anti-bacterial Analysis Control Result Staphylococcus

aureus

ATCC 6538The Number of bacteria immediately after

inoculatio2.1 x 10⁴ - Bacterial after 18H of incubation 9.3 x 10 <20 Bacteriostatic reduction rate - 99.9 Klebsiella

pneumoniae

ATCC 4352The Number of bacteria immediately after

inoculatio1.7 x 10⁴ - Bacterial after 18H of incubation 3.3 x 10 <20 Bacteriostatic reduction rate - 99.9

Reduce

Reduce

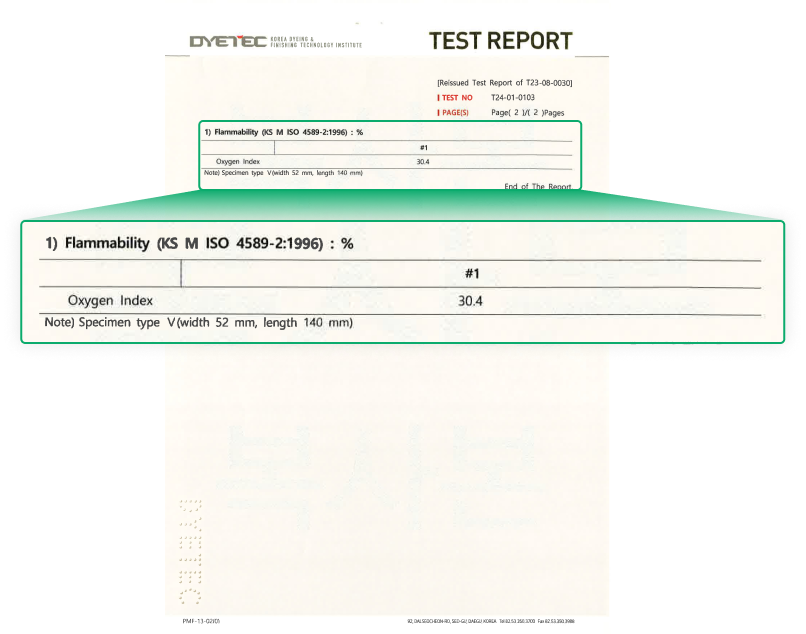

GRS Flame Retardant Nonwoven Fabric

The use of non-halogenated flame retardants (phosphorus-based) ensures no emission of environmental hormones. The simultaneous action in both gaseous and solid states during combustion forms a non-combustible layer on the surface, thereby physically blocking internal heat transfer.

-

Product Name

GRS Flame Retardant Nonwoven Fabric

-

Category / Type

Industrial Material / Nonwoven Fabric

-

Composition

R-PET+FRX Flame Retardant

-

Finish / Weight(g/sqm)

Unprocessed / 15~100

Flame Retardancy Test Results

Sustained Leadership Functionality PP SB Nonwoven Fabric

Bacterial inhibition and adsorption of methylene gas to maintain freshness, far-infrared (FIR) emission and humidity control when in contact with food, delay in aging

-

Product Name

Sustained Leadership Functionality PP SB Nonwoven Fabric

-

Category / Type

Industrial Material / Nonwoven Fabric

-

Composition

PP+ Leading Maintenance Functional Additives

-

Finish / Weight(g/sqm)

Unprocessed / 15~100

Comparative Experiment on Freshness and Quality Changes in Packaging Materials

Peaches wrapped in three types of non-woven fabric packaging materials are placed in commercially available containers and stored under identical conditions. The quality changes over the storage period are then sensorially evaluated.

Experimental Materials: Fruit (Peaches), Fruit Packaging Containers, Three Types of Nonwoven Fabric Packaging Materials (15*15cm)

Commercial Products

PP100%

Developmental Products (Clavis M/B Applied Manufacturing)

Commercial Products

-

Before

-

After

Neat PP

-

Before

-

After

Developmental Products

-

Before

-

After

Commercial Products

-

Before

-

After

Neat PP

-

Before

-

After

Developmental Products

-

Before

-

After

-

Decay Rate for Each Packaging Material at Room Temperature

Table on Decay Rate for Each Packaging Material at Room Temperature Category Commercial Products Neat PP Developmental Products Number of Samples 6 6 6 Number of Decayed Samples 3 2 1 Decay Rate(%) 50 33 16 -

Verification of Leading Maintenance Functionality in Clavis Developmental Product Against Decay and Deterioration

Approximately Threefold Improvement in Freshness Compared to Commercial Products