{{ pageName }}

Development of Eco-friendly Biodegradable Material Using Specialized Resin: Low-Temperature Melt-Blown PLA Material

(PLA 100% Melt-blown Nonwoven Fabric)

01.

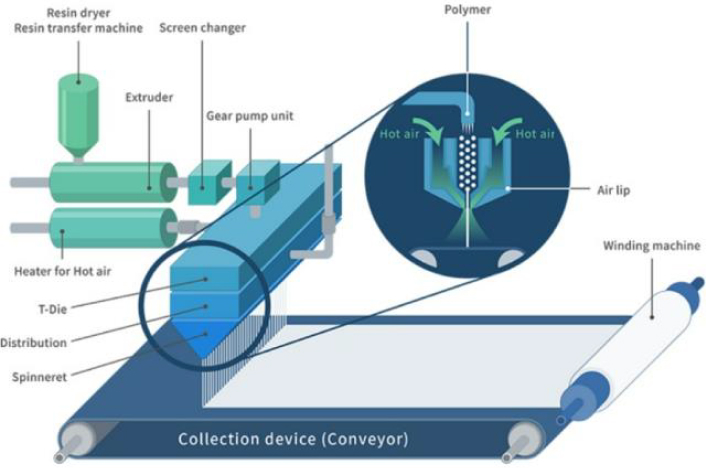

Processing Improvement (Reduction in processing temperature and carbide formation)

02.

Reduced Fiber Diameter Compared to Conventional PLA Resin (Possible finer fiberization due to increased fluidity)

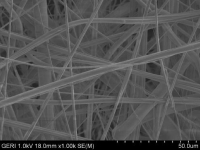

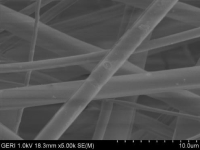

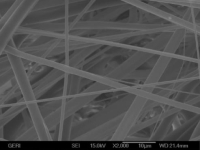

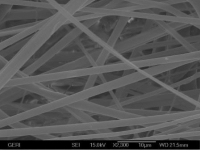

SEM image

Nonwoven fiber diameter distribution

below 5 µm

PLA (x1.0k)

PLA (x5.0k)

PLA (x20.0k)

PLA (x23.0k)

Product Performance

Superior performance and melt-blown processing capabilities compared to commercially available Melt-blown Grade PLA resin.

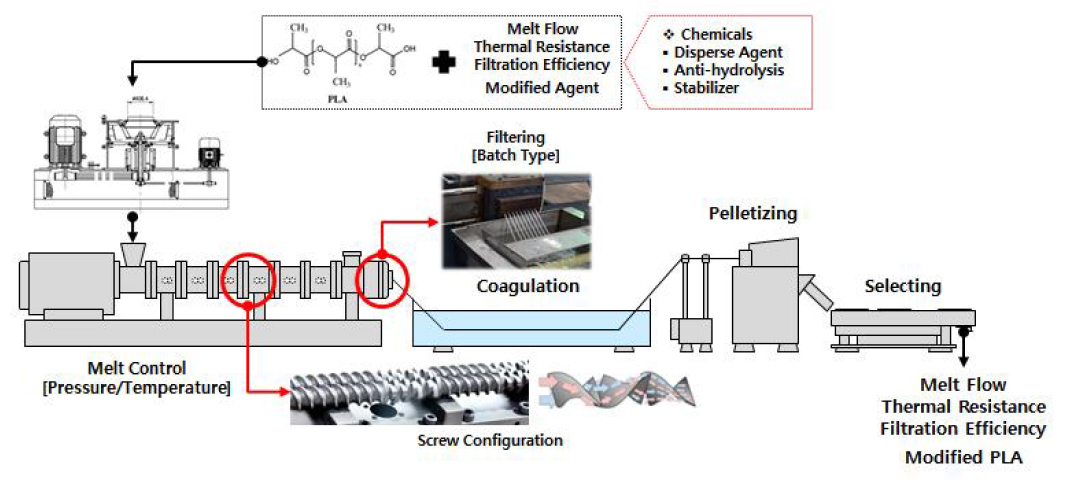

Clavis modification technology allows for high melt flowability suitable for low-temperature melt-blown (230°C, securing MI grades between 450 to 5,000 g/10min).

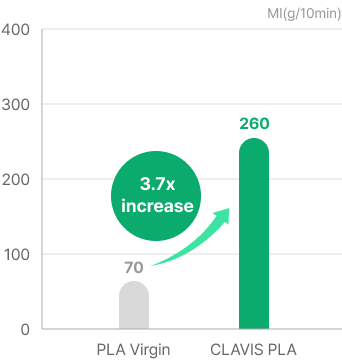

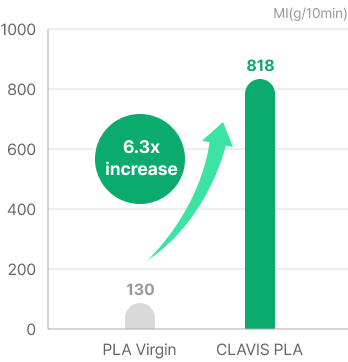

Approximately 6.3 times improvement in melt flow index (MI) at 230°C, reaching 800 g/10min, compared to Virgin (L-105).

210 ℃, 2.16 kg

230 ℃, 2.16 kg

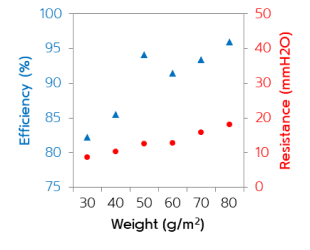

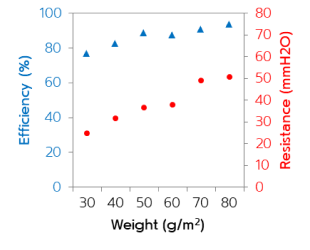

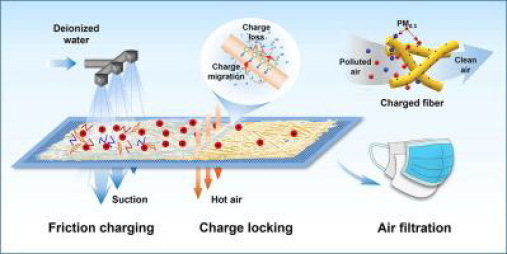

Improved filtration efficiency after hydro-charging (development of biodegradable melt-blown filtration materials possible).

Pre-charging efficiency of 85.5% and pressure drop of 10.4mmH2O observed for Clavis modified PLA and PLA Electret materials.

Anticipated achievement of KF 94 level performance after hydro-charging (analysis underway).

Comparison of Melt-Blown Nonwoven Performance (Pre-charging)

| Category | 30 gsm | 40 gsm | 50 gsm | Remarks | ||

|---|---|---|---|---|---|---|

| 1200 | 1200+C | 1200+C | 1200 | 1200+C | ||

| Filtration Efficiency(%) | 73.6 | 82.2 | 85.5 | 88.3 | 94.1 | Flow Rate 32 L/min |

| Pressure Drop(mmH2O) | 6.7 | 8.7 | 10.4 | 11.5 | 12.6 | |

Flow Rate 32 L/min

Flow Rate 95 L/min

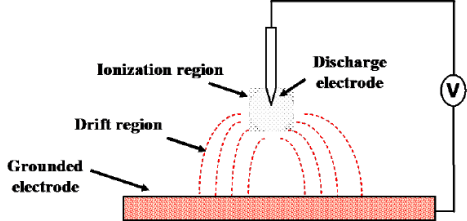

Electro-charging

Dry corona/high-voltage charging introduces surface charge, forming electrets.

Hydro-charging

Wet polar spraying jet introduces surface charge, forming electrets.

Development Results

Development of high melt flowability PLA modified resin suitable for low-temperature melt-blown, using Clavis modification technology.

Prolonged melt-blown of conventional PLA resin led to degradation and thermal deterioration due to inherent molecular structure characteristics.

Modification of conventional PLA material is required to secure high melt flowability (MI) and heat resistance.

Clavis modification technology ensures high melt flowability suitable for low-temperature melt-blown (230°C, ranging from 450 to 5,000 g/10min).

Resin Modification Test Results

| Category | PLA Virgin (L-105) |

econect 101T |

econect_102T | |||||

|---|---|---|---|---|---|---|---|---|

| 800 | 1200 | 1800 | 2000 | 5000 | ||||

| MI (g/10min) |

210℃ | 70 | 148 | 260 | 393 | 432 | 578 | 891 |

| 230℃ | 137 | 501 | 818 | 1,267 | 1,832 | 2,254 | 5,119 | |

| Color | L | 58 | 62 | 63 | 65 | 67 | 68 | 60 |

| a | -6.7 | -7.6 | -6.5 | -6.1 | -5.6 | -5.7 | -8.9 | |

| b | 3.4 | 3.6 | 4.1 | 4.8 | 5.2 | 4.1 | 5.7 | |

| Melting Temp (℃) | 171.9 | 167.2 | 169.8 | 169.4 | 169.9 | 169.7 | 170.24 | |

| Heat Resistance* (Color b) |

230℃ | 1.4 | 2.9 | 2.1 | 4.1 | 3.8 | 5.0 | 6.9 |

| 250℃ | 2.0 | 12.8 | 8.5 | 12.3 | 12.0 | 12.3 | 19.0 | |

* Heat resistance assessment: Comparison of color after heat treatment at a constant temperature (230/250°C) for a duration (residence time of 5min).

Reason for Development

Limitations of Conventional PLA Material

Lower melt flowability and inherent low heat resistance of PLA compared to conventional PP.

Improvement over Conventional Materials

-

01

Fiber diameter of PLA ↑

-

02

Filtration efficiency ↓

-

03

Processing at high temperatures

-

04

Thermal degradation during the melt-blown process

PLA Properties Comparison

| Category | Meltblown | Spunbond | ||||||

|---|---|---|---|---|---|---|---|---|

| FY201 | FY201 | L130 | LX530 | FY601 | FY602 | |||

| Manufacturer | Total Corbion | BBCA & Futerro | Total Corbion | BBCA & Futerro | ||||

| Physical Properties |

Specific Gravity | 1.24 | 1.24 | 1.24 | 1.24 | |||

| Optical purity [% isomer] | ≥99% (L) | ≥99% (L) | ≥99% (L) | ≥98% (L) | ≥99% (L) | ≥98% (L) | ||

| MFR [g/10min] | 210℃, 2.16kg | 70 | 23 | 23 | ||||

| 190℃, 2.16kg | 30 | 30 | 10 | 10 | 9 | 9 | ||

| Glass Transition Temp. [℃] | 60 | 60 | 60 | 60 | 60 | 60 | ||

| Melt Temp. [℃] | 175 | 175 | 175 | 165 | 175 | 165 | ||

| Mechanical Properties |

Tensile strength [Mpa] | 50 | 50 | 50 | 50 | 50 | 50 | |

| Tensile Modulus [Mpa] | 3500 | 3500 | 3500 | |||||

| Elongation at break [%] | ≤ 5 | ≤ 5 | ≤ 5 | ≤ 5 | ≤ 5 | ≤ 5 | ||

| Notched Impact, 23℃ [kJ/㎡] | ≤ 5 | ≥ 1 | ≤ 5 | ≤ 5 | ≥ 1 | |||