{{ pageName }}

Leading Maintenance PP SB Nonwoven Fabric with Bacterial Inhibition and Ethylene Gas Absorption

(Freshness maintenance function PP SB nonwoven fabric)

01.

Functional masterbatch material incorporating functional inorganic particles with far-infrared emission properties into polymer resin.

02.

Demonstrating freshness and antibacterial effects through far-infrared emission characteristics.

Key Features

Freshness preservation

Prolonged freshness of food items such as vegetables and fruits

Non-toxic

Non-toxic plastic product containing harmless inorganic particles.

Far-infrared emission

Far-infrared (FIR) emission upon contact with food.

Optimal moisture retention

Moisture regulation/aging delay by far-infrared (FIR).

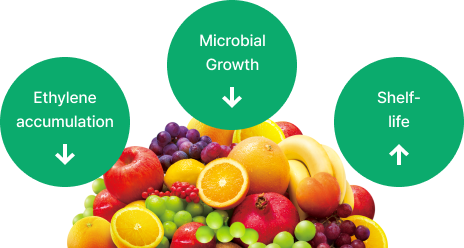

Mechanism for Food Freshness

Maintaining freshness by inhibiting bacteria and absorbing ethylene gas.

Maintaining an appropriate environment through the thermal properties and gas adsorption characteristics at a specific wavelength.

Strong penetration and resonance phenomena of far-infrared activating food cells 2,000 times per minute.

Increased resistance to external factors like bacteria or viruses for prolonged freshness.

-

Accelerated ripening and decay of ethylene gas (C2H4).

-

Far Infrared

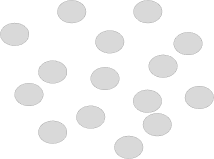

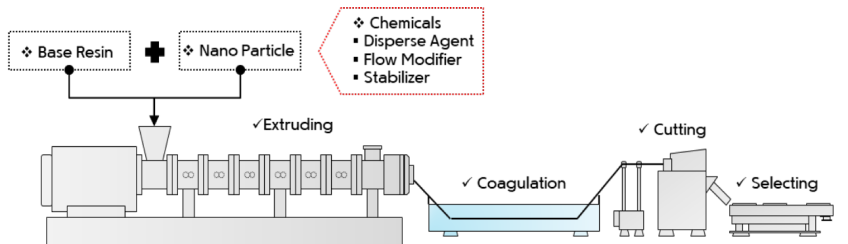

Nanoparticle Dispersion Technology

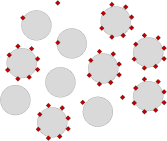

High-efficiency material dispersion technology reflecting the unique properties of nanoparticles.

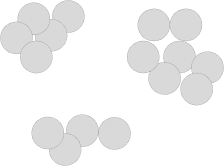

Tendency of nanoparticles to aggregate due to their high surface energy.

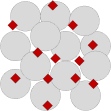

Addition of additives for maximal dispersion and improved compatibility with the polymer matrix.

Optimization of dispersion through internal pressure and shear force application within the extruder.

-

Primary Particle

~20nm

High Surface Energy Of Nanoparticle

-

Aggregate

30~150nm

Chemical Forces

ex. Hydrogen Bonding(Strongly Bound)

-

Agglomerate

1~100um

Physical Interaction Van Der Waals Forces (Weakly Bound)

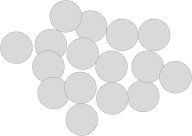

Particle Wetting

Infiltration and wetting of particles into agglomerates

Dispersion

Disintegration of agglomerates through dispersants

Stabilization

Prevention of re-agglomeration of dispersed particles

Screw RPM & Feeding RPM & Extruder Temp. Control

Screw Configuration

Shear Stress & Pressure Control