{{ pageName }}

WEARCOM Co., Ltd. has actively participated in the 2023 Reliability-Based Utilization Support Project (Reliability Voucher), an initiative of the Korea Institute for Advancement of Technology (KIAT).

In collaboration with the Korea Textile Development Institute, WEARCOM has undertaken a research project titled Development and Reliability Assessment of Natural Biodegradable Nonwoven Fabric Using Thermoplastic Cellulosic Materials with Enhanced Physical Properties and Workability.

This endeavor reflects the company's commitment to researching and developing a spectrum of eco-friendly technologies.

Home Compostable Biodegradation

The ambient temperature must be maintained at 25±5℃ throughout the testing period, ensuring that it does not exceed 30℃.

The standard composting conditions align with the industrial composting parameters (ISO 14855-1), which necessitate maintaining a temperature around 58℃ to 60℃, a pH level of 7, and a minimum moisture content of 70%.

WEARCOM Co., Ltd., in its ongoing research at the Korea Textile Development Institute, is conducting a home composting test.

This test diverges from the conventional industrial composting conditions, requiring only the aforementioned ambient temperature of 25±5℃ without the need for additional specific conditions.

Flame Retardant Materials

In response to the intensifying regulations due to environmental stability concerns associated with halogen-based flame retardants, WEARCOM is aligning with the trend of shifting towards non-halogenated flame retardants. The company is producing nonwoven fabrics using phosphorus-based flame retardants. WEARCOM's phosphorus-based flame retardants are distinguished for their excellent flame resistance and are formulated from 100% recycled, eco-friendly materials. These phosphorus-based flame retardants are not only harmless to the human body but also adhere to the Global Recycle Standard (GRS), underlining WEARCOM's commitment to environmentally responsible production practices.

View Product Details

Innovative Materials

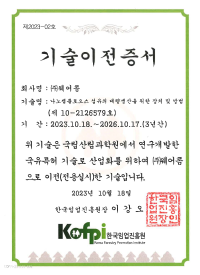

WEARCOM has acquired the exclusive license for the patent Device and Method for Mass Production of Nanocellulose Fibers from the National Institute of Forest Science.

This patent pertains to a process that utilizes physical methods, as opposed to chemical ones, for the production of Nanocellulose Fibers (CNF), spanning from the grinding to the homogenization stages.

Furthermore, the raw materials used in this process, including cellulose fibers, can encompass a variety of sources such as hardwood and softwood pulp, unbleached pulp, bleached pulp, de-inked pulp, and recycled materials.

This diverse sourcing of raw materials significantly contributes to environmental sustainability, aligning with eco-friendly initiatives.

Registered Patent

10-2018-0086949